Methods & requirements

DBL 7381: The Mercedes-Benz Standard for Corrosion Testing

Corrosion testing determines the resistance of materials to corrosion under specific environmental conditions, like temperature and humidity.

Other accelerating factors can be the presence of chemicals and the pH-level of the salt fog and pluviometry, which are critical parameters outlined in ASTM B117 for salt spray tests.

When selecting a test method, ensuring the controlled environment matches natural outside conditions is crucial for accurate evaluation of protective coating degradation behavior.

Introducing the Standard and Its Purpose

DBL 7381 is a critical Mercedes-Benz standard that defines testing requirements for metallic parts and metal sheets subjected to corrosive environments. This test method classes standard is essential for evaluating coating quality on components manufactured for the automotive industry. From dip coating processes to final coatings assessment, DBL 7381 provides comprehensive guidelines for ensuring long-term durability against extreme corrosive stress conditions.

Relationship with MBN 10494 Testing Framework

The DBL 7381 standard works in close alignment with MBN 10494, particularly MBN 10494 6, which focuses on specialized corrosion tests for vehicle interior components. Together, these standards provide a complete framework for evaluating both exterior and interior components. The MBN 10494 6 section specifically addresses materials and coating systems used in conditions where high corrosive stress is expected, making it invaluable for quality assurance in automotive manufacturing.

Testing Procedures for Various Corrosion Levels Including Very Extreme Corrosive Stress

When implementing a corrosion test under DBL 7381, components subject to different environments require specific assessments. Parts exposed to very extreme corrosive stress, such as those in the engine compartment or engine compartment wall, undergo rigorous cyclic corrosion testing.

Components experiencing particularly high corrosive stress, including roof trim strips and exterior elements, are evaluated with specialized test mixtures. For areas with medium corrosive stress, including many vehicle interior applications, modified protocols are applied.

Test Chamber Requirements

The test chamber requirements for the corrosion cyclic test according to DBL 7381 are stringent to ensure accurate simulation of extreme corrosive stress conditions. The chamber must be capable of maintaining a temperature range from -20°C to 50°C, with a humidity control system that keeps relative humidity between 50% and 90%. This precise control is crucial for replicating the harsh environments that automotive components may encounter.

Additionally, the chamber must be designed to allow uniform exposure of test specimens to the corrosive environment, ensuring consistent results. A robust ventilation system is also necessary to remove any hazardous substances released during testing, maintaining a safe and controlled environment. Compliance with DIN 55635 (VDA 233-102 / “VDA new”) standards is mandatory, ensuring the chamber meets all required specifications.

Organic Coatings Evaluation and Testing

The standard provides detailed guidance for testing organic coatings across various applications. Whether evaluating powder coating performance or cataphoretic dip coating durability, DBL 7381 ensures comprehensive assessment. The test chamber conditions simulate real-world environments to verify that coating systems meet Mercedes-Benz requirements. Test panels with both single or multicoat paint finishes are systematically evaluated to ensure they withstand intended environmental conditions.

Application to Different Metallic Base Materials

DBL 7381 addresses testing requirements for various metallic base materials used in automotive manufacturing. From ferrous materials to light alloys, the standard ensures that metallic parts maintain integrity even under constant thermal load. For zinc alloy coatings and other specialized protective layers, specific test methods assess their resistance to degradation. This comprehensive approach ensures that only the referenced edition of materials and processes meet the stringent requirements.

Differences between DBL 7381.10, DBL 7381.20 and DBL 7381.22

DBL 7381.10 – Climate Cycling & Severe Environmental Exposure

DBL 7381.10 focus on tropical climate cycling with wide temperature ranges and several complementary test procedures.

It includes, for example:

- Temperature cycling from –70°C to +180°C

- NSS & AASS (neutral salt spray / acidified salt spray)

- Condensation water, Kesternich, water immersion

- Mechanical influences: stone-chip, impact resistance, pull-off, cross-cut, cupping deformation

- Designed for very harsh and extreme environments

Typical application:

Components exposed to strong climate variations, e.g., engine bay, underbody, or other severe service environments.

DBL 7381.20 – CCT2 (Corrosion Cycle Test 2)

DBL 7381.20 – CCT2 is a Mercedes-Benz cyclic corrosion test for steel and galvanized components, designed to assess coating systems under accelerated corrosive conditions. It represents Corrosion Cycle Test 2 (CCT2) within the DBL 7381 family of coating and corrosion standards.

It measures coating integrity, weld seam behavior, edge corrosion, and general corrosion performance under a controlled cycle simulating harsh real-world exposure.

This test is more focused and corrosion-specific than DBL 7381.10 (Cycle 1), which also includes climate cycling.

Where it is used

DBL 7381.20 is applied for:

- Galvanized steel parts

- Components with high corrosion exposure, especially on the underbody or in wheel-arch regions

- Multilayer coatings

What the test measures

In extension CCT2 evaluates both qualitative and quantitative corrosion parameters with assessments such as:

- Coating thickness (zinc & e-coat)

- Cross-cut (GT) ratings

- Scratch test (after 24h)

- Surface corrosion (Ri)

- Edge corrosion (inside/outside, above/below)

- Weld seam corrosion (SR)

- Subsurface corrosion (U/2)

- Flange corrosion (FR) after test opening

These parameters together determine how well a coated steel part resists corrosion under accelerated cyclic conditions.

The test cycle of CCT2 DBL 7381.20

CCT2 involves accelerated cyclic corrosion, normally consisting of:

- Periods of salt exposure

- Humidity/condensation cycles

- Drying phases

- Controlled temperature/humidity transitions

While the exact cycle parameters are protected in the Mercedes-Benz standard, the structure aligns with VDA 233-102 (“VDA New”) / DIN 55635 corrosion cycling introduced in the newer DBL 7381 editions.

DBL 7381.22 – KTL-Specific Variant

DBL 7381.22 is used for:

- KTL coating (cataphoretic dip coating) according to Mercedes-Benz specifications

- Common test elements:

-

-

- Cross-cut

- Scratch

- CH 240 h (humidity condensation)

- Cyclic corrosion test – 10 cycles according to DBL 7381

-

Typical application:

Specifically for KTL-coated parts, often at component level, combining mechanical and cyclic corrosion requirements.

| Overall Comparison | |||

|---|---|---|---|

| Version | Focus Area | Typical Test Elements | Typical Application |

| 7381.10 | Climate cycling & extreme environment | Climate cycling –70/+180°C, NSS/AASS, mechanical tests | Highly demanding environments (engine bay, underbody) |

| 7381.20 | Cyclic corrosion (CCT2) | CCT2 on steel, cross-cut, scratch, CH | Pure cyclic corrosion evaluation on steel |

| 7381.22 | KTL coating requirements | Cross-cut, scratch, CH 240 h, 10 cycles | KTL-coated components per Mercedes-Benz |

Test Methods and Quality Control

The test methods outlined in DBL 7381 include both climatic tests and optical tests to evaluate coating performance comprehensively. The production process for components manufactured under this standard must incorporate strict controls to prevent contamination with hazardous substances.

For the category body component group, test panels undergo specialized assessment to verify suitability for painted bodies and individual parts. These rigorous quality controls ensure Mercedes-Benz’s high standards for durability are consistently met.

Test Equipment and Calibration

To conduct the corrosion cyclic test as per DBL 7381, specific equipment is essential. This includes a test chamber that meets the outlined requirements, along with a temperature control system capable of maintaining the specified range of -20°C to 50°C. A humidity control system is also necessary to ensure relative humidity stays between 50% and 90%.

A ventilation system is crucial for removing hazardous substances, while a data acquisition system records all test data for analysis. Regular calibration of the test equipment is vital to ensure accuracy and repeatability. This process must be meticulously documented, ensuring that all equipment functions correctly and provides reliable results.

Operator Training and Qualification

Operators conducting the corrosion cyclic test under DBL 7381 must undergo comprehensive training and qualification. This training covers a thorough understanding of the test standard, equipment operation, and the specific test procedures. Safety protocols are also a critical component of the training, ensuring operators can handle hazardous substances safely.

Qualification involves demonstrating the ability to perform the test accurately and consistently. This process is documented to ensure that only qualified personnel conduct the tests, maintaining the integrity and reliability of the results.

Applications in Automotive Manufacturing

DBL 7381 has significant impacts across the automotive manufacturing process. From dip coating applications to thermally stable single layer finishes, the standard guides coating application examples throughout production.

Process materials must be carefully selected and controlled to ensure compliance with the standard. This is particularly important for components in the engine compartment, where high corrosive stress and coatings decorative requirements must be simultaneously satisfied.

Test Report and Documentation

A detailed test report is essential for documenting the corrosion cyclic test according to DBL 7381. This report must include a comprehensive description of the test procedure, equipment used, and calibration details. It should also cover the preparation of test specimens and a thorough analysis of the test results.

Any deviations or anomalies encountered during the test must be documented, along with conclusions and recommendations based on the findings. The report must be signed and dated by the test operator and archived according to the standard’s requirements, ensuring traceability and accountability.

Implementation and Compliance Requirements

Implementing DBL 7381 requires careful attention to detail in test chamber setup and maintenance. Ferrous materials and single or multicoat finish systems must be regularly evaluated according to the standard’s protocols.

For cataphoretic dip coating processes, specific controls must be in place to ensure consistent quality. Metallic parts across various vehicle applications benefit from these rigorous testing requirements, resulting in superior long-term performance even under high corrosive stress conditions.

Our most common corrosion tests

Have a question? Contact us!

Talk to our corrosion test experts

Are you interested in conducting a test? Feel free to contact us – we’re here to assist you every step of the way.

Joakim Ekström

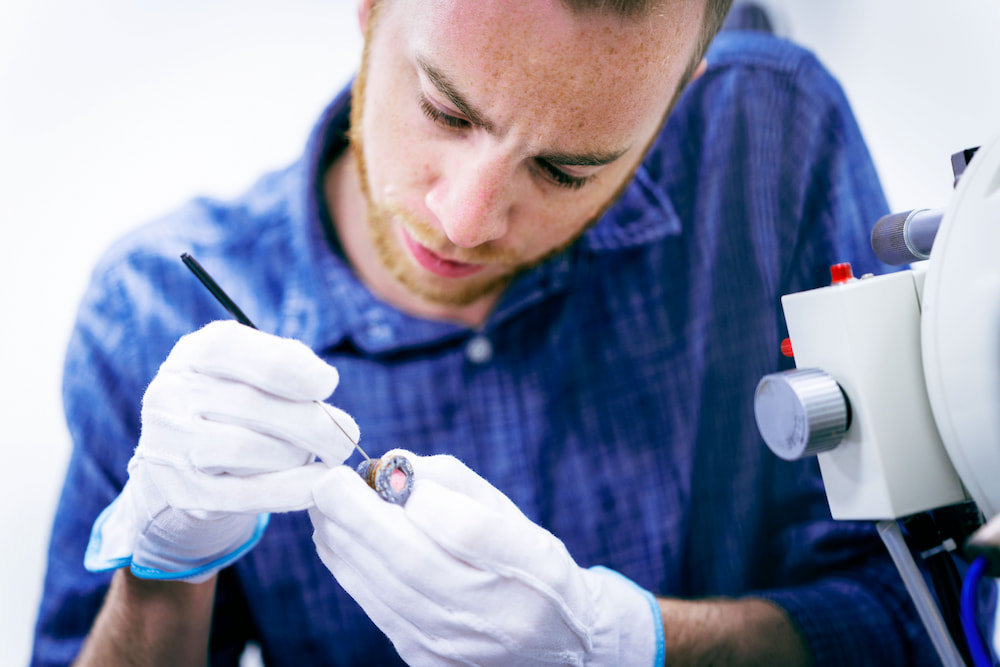

Erik Waltersson

Accredited by SWEDAC

and part of the international accreditation network ILAC

Methods and requirements

We offer a comprehensive and continuously expanding lab-scope of over 300 available test methods and standards.

Laboratory and equipment

Cotec Labs provides a 1200 sqm laboratory facility. Take a closer look at our laboratory

and equipment.

Quality and certificates

We are accredited by Swedac and part of the international accreditation network ILAC.