Methods & requirements

Jaguar Land Rover TPJLR.52.265

Corrosion testing determines the resistance of materials to corrosion under specific environmental conditions, like temperature and humidity. Other accelerating factors can be presence of chemicals and the pH-level of the salt fog and pluviometry.

There are mainly two different types of corrosion test standards, field performance and accelerated corrosion tests. Cotec Labs is focused on different types of standardized corrosion tests.

What is important when choosing a test method is to make sure the controlled environment matches the natural outside environment in terms of behaviour of the protective coating when it degrades. Since the methods used in a laboratory environment are accelerated, studies must underpin the extrapolation of test duration.

What is the TPJLR 52.265 test?

TPJLR.52.265 is a corrosion test standard developed for environmental testing of vehicle parts. The Jaguar Land Rover TPJLR.52.265 standard defines an accelerated corrosion test (ACT) method to be used in assessing the corrosion resistance of metals in environments where there is a significant influence of chloride ions, mainly as sodium chloride from a marine source or by winter road deicing salt. There are several industries that can benefit from using this method. In this standard the term “metal” refers to metallic materials with or without corrosion protection. The applied rain that is acidified in combination with drying and wetting is what many applications must withstand, not just within the automotive industry.

The Jaguar Land Rover TPJLR.52.265 specifies a test procedure to be used in conducting the accelerated corrosion test to simulate atmospheric corrosion conditions in a controlled way.

The accelerated corrosion test is applicable to

- metals and their alloys

- metallic coatings

- chemical conversion coatings

- organic coatings on metals

The method is suitable for comparative testing in the optimization of surface treatment systems for test panels, specially designed test objects and components. It is considered to be a universal method when it comes to testing complex products- and geometries. Many different reactive materials in the same product makes weather simulation very valuable.

Test procedure and assessment by ISO 10289

Jaguar Land Rover laboratory accelerated cyclic corrosion test is performed in test chambers where atmospheric corrosion conditions are simulated by using influence of chloride ions from a sprayed salt solution and variation in humidity and temperature in a controlled way. The test objects are tested during a defined exposure time. The exposure time in the chamber is described by requirement standards and depends amongst other on the surface treatment of the test samples. The accelerated corrosion test is finished when the specified exposure time for the test samples is reached. Upon finishing of the corrosion testing the samples are evaluated for corrosion resistance.

One way to inspect and evaluate the appearance of the coating and base metal corrosion on the tested samples is ocularly by ISO 10289. This method is widely used as an instrument for evaluation when testing inorganic coated items like, screws, washers, nuts, bolts and brackets. The appearance, often seen as white corroded Zink (Zn), is estimated by area (RA). The Zink usually corrodes when the passivation has degraded. When coated layer of Zn, ZnNi, or Zink flakes coating has lost the battle against moisture and oxygen, with the help of salt and acidification, red rust usually appears on the samples. Like the RA-grade of the Zn the area where red rust is present Rp is evaluated (Rust Protection). When it comes to paint and powder coating, another suitable evaluation method is 4628-1, Designation of quantity and size of defects, and of intensity of uniform changes in appearance. Many methods focus on blisters, general corrosion, pitting, edge corrosion and propagation from scribe.

Test Cycle

During a corrosion resistance test according to TPJLR.52.265 the atmospheric corrosion conditions are accelerated using a cyclic corrosion test method in a controlled chamber. The test cycles consist of controlled humidity and temperature cycling with application of salt by rain phase. One test cycle corresponds to one week of testing. The one-week test cycle is composed of two twelve-hour sub-cycles, where sub-cycle 1 consists of controlled humidity and temperature cycling, while sub-cycle 2 also contains the salt mist application (with a 6 hours wet phase). The variation in temperature is 35-45 degrees C and the relative humidity (humidity % RH) reaches from 50 to 90. The rain corresponds to pH 4,2 and 1% NaCl concentration. After having been sprayed until wet, all objects are air dried from visible wetness in order to regain climate control. The humidity and temperature levels of the climate chamber during a test cycle is continuously monitored. The humidity and temperature sensors reflect the climate conditions in the actual test area.

Corrosion resistance requirements

Corrosion resistance requirements for samples tested by TPJLR.52.265 are specified by requirement standards. The requirements depend on coating of the samples and the environment the samples are exposed to during position in the jlr vehicles.

Example of requirement standards where accelerated corrosion testing by test method TPJLR.52.265 is required are for example:

- 51.5254 Performance Requirements of Painted Underbody and Service Parts

Our most common corrosion tests

Talk to our corrosion test experts

Are you interested in conducting a test? Feel free to contact us – we’re here to assist you every step of the way.

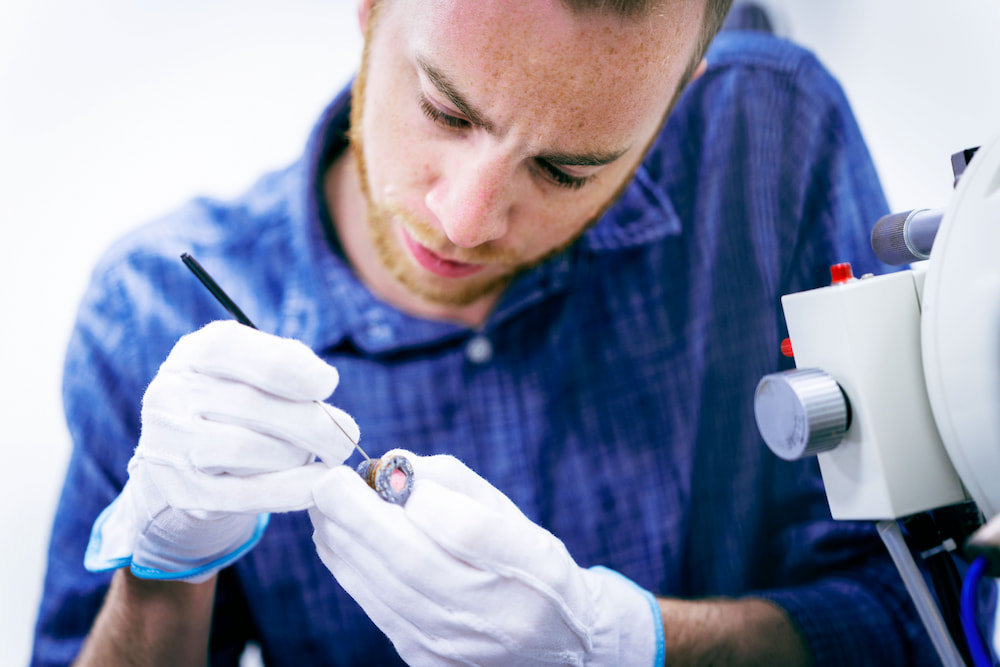

Joakim Ekström

Erik Waltersson

Accredited by SWEDAC

and part of the international accreditation network ILAC

Methods and requirements

We offer a comprehensive and continuously expanding lab-scope of over 300 available test methods and standards.

Laboratory and equipment

Cotec Labs provides a 1200 sqm laboratory facility. Take a closer look at our laboratory

and equipment.

Quality and certificates

We are accredited by Swedac and part of the international accreditation network ILAC.