Methods & requirements

Scania STD 4113 test

Corrosion testing determines the resistance of materials to corrosion under specific environmental conditions, like temperature and humidity. Other accelerating factors can be presence of chemicals and the pH-level of the salt fog and pluviometry.

There are mainly two different types of corrosion test standards, field performance and accelerated corrosion tests. Cotec Labs is focused on different types of standardized corrosion tests.

What is important when choosing a test method is to make sure the controlled environment matches the natural outside environment in terms of behaviour of the protective coating when it degrades. Since the methods used in a laboratory environment are accelerated, studies must underpin the extrapolation of test duration.

Introduction to Scania STD 4113

Scania STD 4113 is a critical standard that defines coating- and corrosion resistance requirements for vehicle components. This standard is fundamental for ensuring the durability and reliability of metals, paint systems, and surface treatments used in automotive applications. Corrosion testing under Scania STD 4113 provides manufacturers with crucial data about how materials will perform under various environmental conditions, including fluctuating humidity levels. The standard is widely respected across the automotive industry, with many manufacturers including VW implementing similar testing protocols for their cars.

Corrosion Testing Methodology

Corrosion testing according to Scania STD 4113 involves rigorous evaluation of materials in controlled environments. The testing procedures simulate real-world conditions that vehicle parts encounter during their service life. These tests measure how different metals react to various environmental factors, with special attention to humidity variations.

Testing equipment typically includes cyclic testing chambers of ControlArt type as per cycle Scania STD 4445 or Scania STD 4319, allowing for accelerated corrosion testing that can predict long-term performance. In more rare cases when requirements are set at the lowest level, described as Scania STD4111-B1-PP, ISO 6270-2 CH is assigned.

Key Components and Requirements

The requirements specified in Scania STD 4113 address various aspects of corrosion resistance for automotive components. The standard carefully considers factors such as shaft diameter, housing diameter, and bearing clearance when evaluating parts.

For metals like steel and aluminum, the standard defines specific testing protocols to ensure optimal corrosion resistance. Surface treatments including phosphate coatings and primer applications are also evaluated according to strict criteria. These requirements extend to castings and other specialized components used in vehicle manufacturing.

Testing Procedures and ISO Alignment

Corrosion testing under Scania STD 4113 aligns with numerous ISO standards, ensuring consistency and reliability in results. The testing procedures involve precise control of humidity, temperature, and salt spray application. These procedures are designed to evaluate how different metals and surface treatments respond to corrosive environments.

The standard sets clear parameters for shaft diameter, housing diameter, and bearing clearance measurements during testing. Manufacturers must meet these requirements to ensure their parts achieve suitable corrosion resistance performance.

Application in Vehicle Manufacturing

Vehicle manufacturers apply Scania STD 4113 standards to ensure the durability of critical components. The standard is particularly relevant for parts exposed to harsh environments where corrosion resistance is essential. Manufacturers utilize the testing data to select appropriate metals, paints, and surface treatments for different applications.

The requirements guide decisions about phosphate treatments, primer selection, and other corrosion protection strategies. By following these standards, manufacturers can ensure their parts meet or exceed the expected service life.

Assessment and Evaluation Methods

Assessment of corrosion resistance under Scania STD 4113 utilizes standardized evaluation criteria aligned with ISO guidelines. The evaluation examines various aspects including paint adhesion, metal deterioration, and the effectiveness of phosphate treatments.

Testing results are categorized based on standard size specifications and diameter measurements. The assessment considers both visual inspection and quantitative measurements to determine if components meet the requirements.

This comprehensive evaluation ensures that only suitable materials and treatments are approved for use in vehicle manufacturing.

Comparative Analysis with Other Standards

When compared to other standards like VW TL specifications, Scania STD 4113 maintains distinct requirements for corrosion resistance. The testing methodologies share similarities with other automotive standards but are specifically tailored to Scania’s quality requirements.

The standard incorporates elements from ISO corrosion testing frameworks while maintaining unique specifications for humidity exposure and salt application. This comparative approach ensures that parts meeting Scania STD 4113 will deliver reliable performance across various operating conditions.

Humidity and Environmental Factors

Humidity control is a critical aspect of corrosion testing under Scania STD 4113. The standard defines precise humidity levels that simulate diverse environmental conditions vehicles encounter during operation. Testing protocols measure how different metals and surface treatments perform under varying humidity exposures.

The requirements specify how humidity cycles should be implemented during corrosion testing to accurately predict real-world performance. These detailed specifications ensure that components demonstrate suitable corrosion resistance across all anticipated operating environments.

Paint Systems and Surface Treatments

Scania STD 4113 provides detailed requirements for paint systems and surface treatments. The standard specifies testing procedures for evaluating paint adhesion and durability under corrosive conditions. Phosphate pre-treatments are particularly emphasized as crucial for achieving optimal corrosion resistance. The requirements address how primer layers interact with topcoats and substrate metals to form an effective corrosion barrier. Testing evaluates how these paint systems perform when applied to different metals and standard size components.

Compliance and Quality Assurance

Manufacturers must demonstrate compliance with Scania STD 4113 through documented corrosion testing results. The standard outlines quality assurance procedures that must be followed to verify corrosion resistance claims. These requirements ensure consistent performance across production batches of vehicle parts.

Compliance testing examines how metals, paints, and treatments work together to provide comprehensive corrosion protection. Manufacturers who meet these standards can confidently sign off on the durability of their components.

Advanced Testing Technologies

Modern corrosion testing for Scania STD 4113 utilizes advanced technologies to evaluate corrosion resistance with greater precision. These technologies allow for more accurate measurement of clearance changes and diameter variations resulting from corrosion processes. The testing equipment can simulate various environmental conditions including humidity fluctuations and salt exposure.

These advanced methods help manufacturers identify suitable materials and treatments for specific applications. The requirements for testing technologies ensure consistency and reliability in evaluating corrosion resistance performance.

Industry Applications and Benefits

Across the automotive industry, Scania STD 4113 provides significant benefits for manufacturers seeking to enhance corrosion resistance.

The standard helps manufacturers select appropriate metals and treatments for different vehicle parts. By meeting these requirements, companies can reduce warranty claims related to corrosion issues.

The testing protocols allow manufacturers to predict component performance before vehicles enter service. These standards ultimately contribute to more durable and reliable vehicles for consumers.

Global Recognition and Implementation

Scania STD 4113 has achieved global recognition as a reliable standard for corrosion resistance evaluation. The standard’s alignment with ISO frameworks facilitates international implementation and acceptance. Many manufacturers, including those producing cars for the global market, reference these standards in their specifications.

The requirements have influenced corrosion testing practices across the automotive industry. This global recognition ensures that parts manufactured according to Scania STD 4113 can be used in vehicles worldwide.

Documentation and Traceability Requirements

Comprehensive documentation is essential for demonstrating compliance with Scania STD 4113. The standard specifies record-keeping requirements for all corrosion testing activities. These documents must include detailed information about metals tested, treatments applied, and testing conditions.

The documentation allows customers to verify that components meet applicable corrosion resistance requirements. This traceability is particularly important for critical components where corrosion resistance directly impacts safety and performance.

Our most common corrosion tests

Have a question? Contact us!

Talk to our corrosion test experts

Are you interested in conducting a test? Feel free to contact us – we’re here to assist you every step of the way.

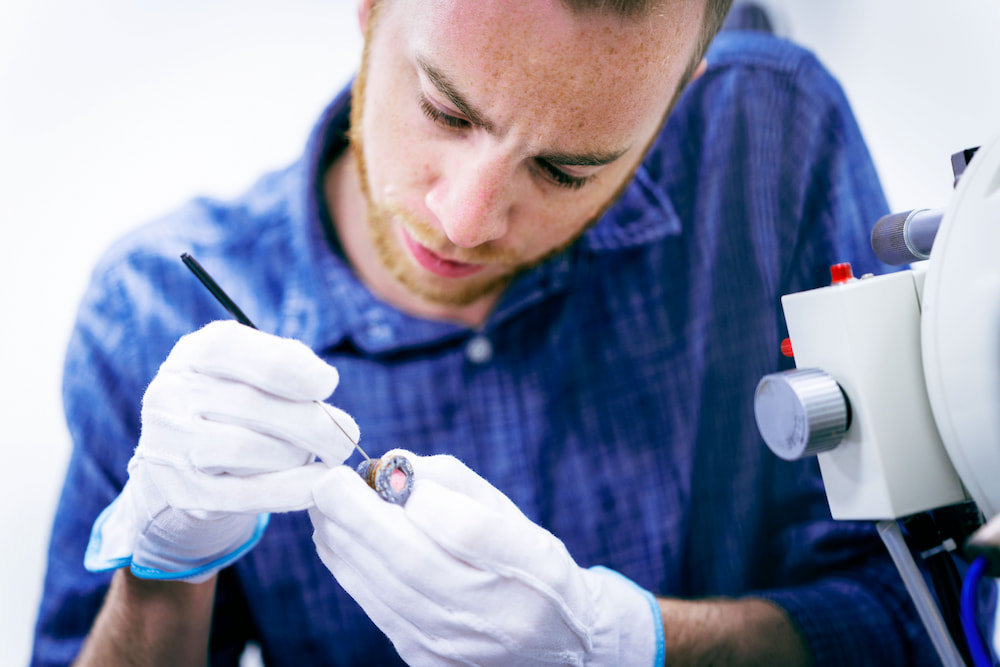

Joakim Ekström

Erik Waltersson

Accredited by SWEDAC

and part of the international accreditation network ILAC

Methods and requirements

We offer a comprehensive and continuously expanding lab-scope of over 300 available test methods and standards.

Laboratory and equipment

Cotec Labs provides a 1200 sqm laboratory facility. Take a closer look at our laboratory

and equipment.

Quality and certificates

We are accredited by Swedac and part of the international accreditation network ILAC.