Methods & requirements

Scania STD 4165 test

Corrosion testing determines the resistance of materials to corrosion under specific environmental conditions, like temperature and humidity. Other accelerating factors can be presence of chemicals and the pH-level of the salt fog and pluviometry.

There are mainly two different types of corrosion test standards, field performance and accelerated corrosion tests. Cotec Labs is focused on different types of standardized corrosion tests.

What is important when choosing a test method is to make sure the controlled environment matches the natural outside environment in terms of behaviour of the protective coating when it degrades. Since the methods used in a laboratory environment are accelerated, studies must underpin the extrapolation of test duration.

Introduction to Scania STD 4165

As an accredited testing laboratory serving the automotive industry, we play a crucial role in verifying that components meet strict surface treatment requirement standards.

One of the standards we work with is Scania STD 4165, which outlines requirements for flake coatings and electroplated zinc coatings – critical surface treatments for ensuring long-term durability in harsh environments.

Scania STD 4165 applies to both general applications and highly specific use cases. Our job as a testing lab is to conduct repeatable, unbiased tests to verify compliance – from appearance and chemical resistance to friction, electrical conductivity, and hydrogen embrittlement resistance.

Key Features of Scania STD 4165

Scania STD 4165 provides comprehensive specifications for surface treatment and corrosion protection of metal components. This standard outlines crucial requirements for fasteners, screws, nuts and similar parts that require specialized treatment to ensure optimal performance and longevity.

Core Requirements – Chapter 3 Testing

All surface treatments covered by STD 4165 must meet baseline performance criteria across several dimensions:

- Chemical Resistance – We test components for resistance to substances such as deionized water, diesel fuel, engine coolant, isopropyl alcohol, and alkaline cleaning agents.

- UV Resistance – Coatings are exposed to 800 hours of xenon arc light (per ISO 4892-2) to simulate sunlight exposure.

- Corrosion Resistance – A critical part of our work. We use both ISO 6270-2 (humidity chamber) and Scania’s own accelerated corrosion test (STD4319) to evaluate white and red rust development. Evaluations are made using ISO 10289 visual rating standards.

Tailored Testing for Specific Requirements

Some components – particularly those located in engine bays or electrical grounding points – have elevated requirements. We test:

- High-Temperature Resistance – Up to 300°C exposure with no degradation in corrosion protection.

- Electrical Conductivity – Resistance levels are measured across fasteners, following the classifications in STD4472. For highly conductive applications, Class II requirements allow a maximum resistance of 2 mΩ across paired fasteners.

Fasteners and Banjo Screws – High Standards Apply

Scania places special focus on threaded components. We regularly test:

- Friction and Clamping Force – Using STD4419, we verify that the coating supports proper torque and joint stability.

- Hydrogen Embrittlement – Fasteners with strength class ≥ 10.9 must undergo post-coating heat treatment and testing according to ISO 15330.

- Coating Thickness and Tolerances – We ensure dimensional accuracy is preserved after coating, especially on threaded surfaces.

Color coding and part marking are also reviewed according to Scania drawings, ensuring components can be correctly identified during assembly.

Structured Reporting – Complete and Transparent

Our verification reports follow the template outlined in Annex A of STD 4165. This ensures clear, traceable communication with both Scania and the component supplier. It’s not just about passing tests – it’s about providing assurance, accountability, and data-backed quality

Conclusion

Scania STD 4165 isn’t just a technical document – it’s a blueprint for surface reliability in demanding environments. As a testing partner, we ensure that every component meets the highest standards for performance, safety, and longevity.

Our most common corrosion tests

Have a question? Contact us!

Talk to our corrosion test experts

Are you interested in conducting a test? Feel free to contact us – we’re here to assist you every step of the way.

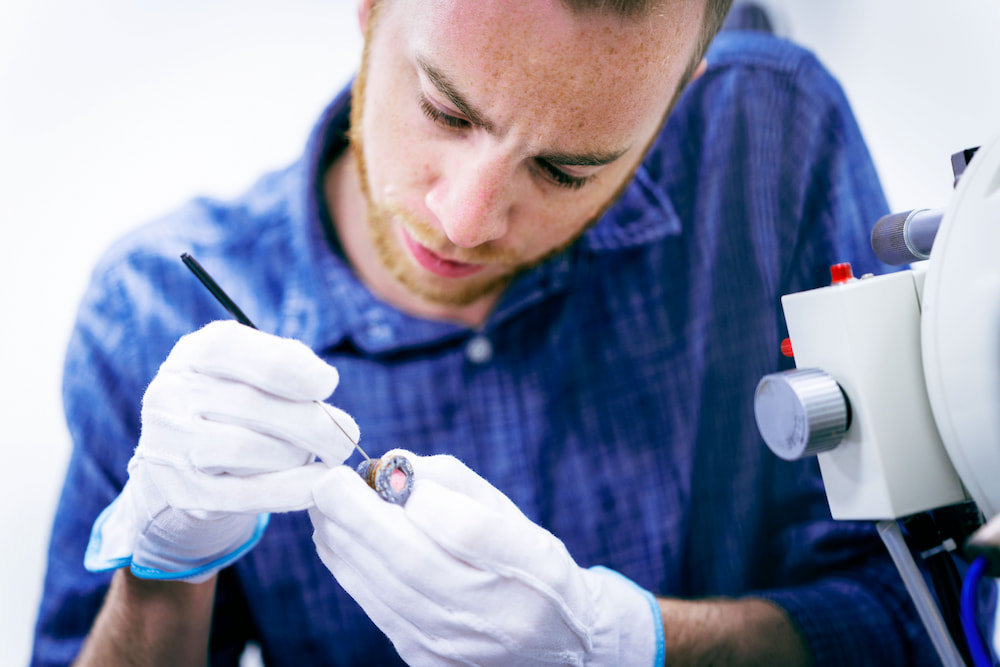

Joakim Ekström

Erik Waltersson

Accredited by SWEDAC

and part of the international accreditation network ILAC

Methods and requirements

We offer a comprehensive and continuously expanding lab-scope of over 300 available test methods and standards.

Laboratory and equipment

Cotec Labs provides a 1200 sqm laboratory facility. Take a closer look at our laboratory

and equipment.

Quality and certificates

We are accredited by Swedac and part of the international accreditation network ILAC.