Methods & requirements

Volvo standard VCS 1027,1449 test

Corrosion testing determines the resistance of materials to corrosion under specific environmental conditions, like temperature and humidity. Other accelerating factors can be presence of chemicals and the pH-level of the salt fog and pluviometry.

There are mainly two different types of corrosion test standards, field performance and accelerated corrosion tests. Cotec Labs is focused on different types of standardized corrosion tests.

What is important when choosing a test method is to make sure the controlled environment matches the natural outside environment in terms of behaviour of the protective coating when it degrades. Since the methods used in a laboratory environment are accelerated, studies must underpin the extrapolation of test duration.

Accelerated corrosion testing by Volvo VCS 1027,1449, ACT II

The test standard Volvo VCS 1027,1449 describes a test method called ACT II which is an abbreviation of accelerated corrosion test, ACT, version II, and is a cyclic corrosion test method used for testing the corrosion resistance on vehicle parts. The standard Volvo standard VCS 1027,1449 defines a laboratory accelerated atmospheric corrosion test method to be used in assessing corrosion resistance of metals influenced by chloride ions from salt spray solution. The test is performed by simulating atmospheric corrosion conditions in a controlled way and it serves as a general-purpose atmospheric corrosion test and applies to a variety of materials, coatings, and interactions of materials, both in the form of test pieces or designed components. The test can be used as a design verification method to:

- Develop and qualify new corrosion resistant products

- Develop new pretreatments and finishing processes

- Select materials and

- Perform quality control of the finished product.

Test procedure and assessment

Samples to be tested for corrosion resistance according to Volvo VCS 1027,1449, are tested in controlled climate chambers during a defined exposure time. The exposure time in the test chamber is described by requirement standards and requirement level and depends amongst other on the surface treatment of the test samples.

The accelerated corrosion test is finished when the specified exposure time for the test samples is reached. Upon finishing the corrosion testing the samples are evaluated for corrosion resistance. Several assessments are applicable to evaluate corrosion resistance for example by evaluation general corrosion, propagation from scribe and spontaneous propagation at edges.

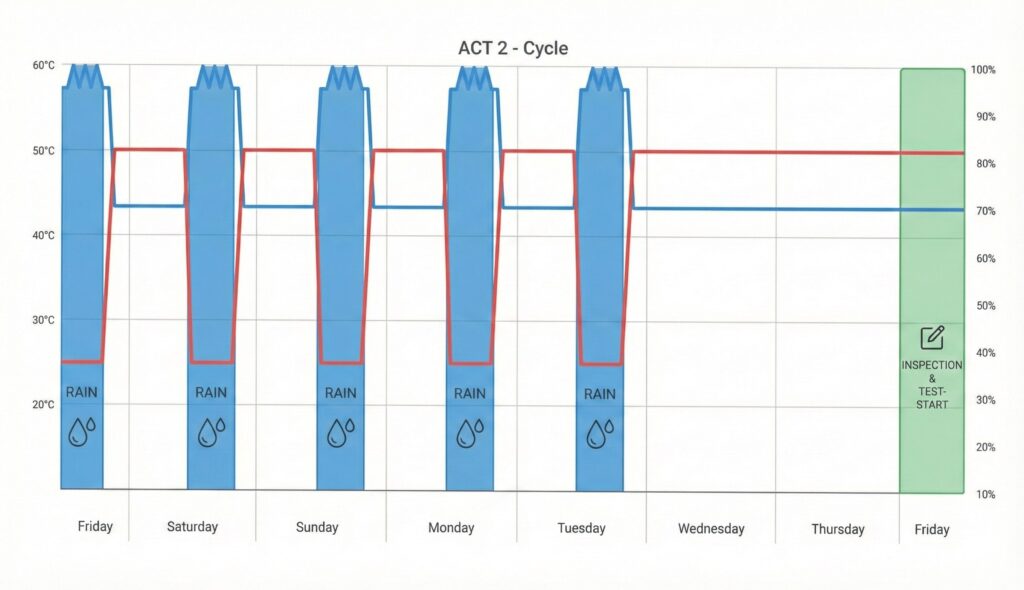

Test cycle

During a cyclic corrosion resistance test according to Volvo VCS 1027,1449 the atmospheric corrosion conditions are accelerated using a cyclic corrosion test method in a controlled chamber.

The test cycles consist of controlled humidity and temperature cycling with application of salt solution by rain phase containing sodium chloride. One test cycle corresponds to one week of testing. The one-week test cycle is composed of two twelve-hour sub-cycles. Sub-cycle 1 consists of controlled and intermittent exposure to varied temperature and humidity, combined with salt application by salt spray exposure that consist of 0.5% NaCl solution. Sub-cycle 2 contains of constant temperature and humidity.

The variation in temperature is 25-50 degrees C and the relative humidity (humidity % RH) reaches from 70 to 95. The complete one-week test cycle consists of 5 repetitions of sub-cycle 1 followed by 2 repetitions of sub-cycle 2.

| Phase | Duration | Conditions |

|---|---|---|

| Sub-cycle 1 (Wet) | 6 hours | 25°C, 95% RH. Intermittent salt spray (0.5% NaCl). |

| Transition | 2.5 hours | Gradual change to 50°C, 70% RH. |

| Sub-cycle 2 (Dry) | 15.5 hours | Constant 50°C, 70% RH. |

| Weekend Phase | 48 hours | Constant 50°C, 70% RH (Days 6–7). |

Difference between Volvo Cars ACT I (VCS 1027,149) and ACT II (VCS 1027,1449)

While both Volvo ACT I (VCS 1027,149) and Volvo ACT II (VCS 1027,1449) are cyclic corrosion tests developed to simulate corrosive environments containing sodium chloride, they represent different generations of testing methodology with distinct parameters.

ACT I (STD 423-0014) is the Volvo Trucks version of VCS 1027,149. It utilizes a 1% NaCl solution, pH 4.2. Within one week two full cycles are completed. These cycles involve controlled humidity and temperature changes, along with defined salty rain-phases. It has historically been used for general durability testing of chassis components, and fasteners. It is still an effective method when testing components constructed form different materials with various coating present.

ACT II (VCS 1027,1449) is a more advanced accelerated corrosion test, equivalent to Scania STD4445. It employs a lower salt concentration (0.5%) but introduces a more complex humidity cycle, with elongated dry phases. This method is designed to provide a better correlation with atmospheric corrosion caused in crevices, among thinner substrates, and substrates of Aluminum.

ACT 2 test cycle

Key technical differences

| Parameter | Volvo Cars ACT I (VCS 1027,149) | Volvo Cars ACT II (VCS 1027,1449) |

|---|---|---|

| Salt Concentration | 1.0% NaCl | 0.5% NaCl |

| Cycle Structure | 1/2-week full cycle (incl. sub-cycles) | 5-day active cycle with daily rain + 48h weekend phase |

| Application Method | Oscillating sprayed rain according to defined periods | Oscillating sprayed rain according to defined periods |

| Climate Control | Controlled Temp/RH cycling/pH, and transitions | Controlled Temp/RH cycling, transitions, and prolonged dry phases |

| Max Temperature | 45°C | 50°C |

| Harmonization | Volvo STD 423-0014, Scania STD4319 | Equivalent to Ford CETP 00.00-L-467, Scania STD4445, Volvo STD 423-0069 |

Evolution of the test standard

The industry shift towards ACT II is driven by the need for test methods that better replicate field dynamics compared to earlier standards used in the Passenger Car Sector.

- Environmental Correlation: ACT II is designed to simulate the variations of a natural environment more closely. The inclusion of specific transitions between wet and dry phases aims to recreate the mechanisms of atmospheric corrosion propagation found in field conditions.

- Stress on Coatings: The test includes a 15.5-hour dry phase at 50°C and 70% RH. This extended exposure to controlled humidity and heat is effective in evaluating the propagation of corrosion from scribe marks and edges on coated panels.

- Industry Harmonization: Developed in conjunction with Ford, the VCS 1027,1449 standard allows suppliers to utilize a unified testing protocol (equivalent to CETP 00.00-L-467) to validate components for multiple OEMs.

Corrosion resistance requirements

Corrosion resistance requirements for samples tested by Volvo VCS 1027,1449 are specified by requirement standards. The requirements depend on the substrate and coating of the samples and the environment the samples are exposed to during position in the vehicle.

Example of requirement standards where accelerated corrosion testing by test method Volvo 1027,1449 ACT II is required are:

- Volvo VCS 5737,19

- Volvo VCS 5771,5

- Volvo VCS 5751,7

Frequently Asked Questions About Volvo VCS 1027,1449 (ACT2)

What is the exact test cycle structure for Volvo VCS 1027,1449?

The Volvo VCS 1027,1449 test follows a precise 7-day cycle that is repeated throughout the test duration. The first 5 days consist of repeated 24-hour cycles with three phases: a 6-hour wet phase at 25°C and 95% relative humidity with intermittent 0.5% sodium chloride spray, followed by a 2.5-hour climate transition phase, and then a 15.5-hour dry phase at 50°C and 70% relative humidity. The final 2 days maintain constant conditions of 50°C and 70% relative humidity for 48 hours.

How does Volvo VCS 1027,1449 differ from VCS 1027,149?

VCS 1027,1449 (ACT-2) uses a 0.5% sodium chloride solution concentration and features a complex 7-day cycle with weekend phases, while VCS 1027,149 (ACT-1) uses a 1% sodium chloride solution with continuous weekly cycling. ACT-2 is typically specified for more advanced coating systems and components requiring extended durability validation. The constant conditions during weekends are similar to the conditions that occur in reality. This is particularly evident in details with crevices where water can accumulate for a longer period, which are put to the real test.

Is Volvo VCS 1027,1449 equivalent to any Ford testing standards?

Yes, Volvo VCS 1027,1449 was developed in conjunction with Ford Motor Company and is considered equivalent to Ford CETP 00.00-L-467. This equivalency allows suppliers to qualify parts for both Volvo and Ford using a single test protocol, streamlining the certification process for automotive suppliers.

What calibration requirements apply to VCS 1027,1449 testing equipment?

Test chambers must undergo regular calibration procedures including bimonthly and annual validation to ensure temperature and humidity measurement accuracy. These calibrations verify that the chamber maintains precise environmental conditions within specified tolerances throughout the test duration.

How are test samples evaluated after VCS 1027,1449 exposure?

Sample evaluation includes multiple assessment methods: visual assessment of general corrosion across the entire surface, evaluation of corrosion propagation from deliberate scratches (scribes), assessment of edge corrosion where base material is exposed, and quantitative analysis measuring corrosion area and depth according to specified acceptance criteria.

What types of materials and coatings can be tested using VCS 1027,1449?

The standard applies to metals and their alloys, metallic coatings such as zinc and zinc-nickel, chemical conversion coatings, and organic coatings applied to metal substrates. It’s suitable for both standardized test panels and actual vehicle components including body panels, chassis parts, and fasteners.

How long does a typical Volvo VCS 1027,1449 test take to complete?

Test duration varies based on coating performance requirements and specific Volvo material specifications. Basic coating systems may require 6-12 weeks of exposure, while premium coatings designed for extended service life may need 24+ weeks of testing to demonstrate adequate corrosion resistance.

What environmental conditions does VCS 1027,1449 simulate

The test simulates harsh atmospheric corrosion conditions with high concentrations of chloride ions, particularly those encountered from marine environments and winter road de-icing salt exposure. The alternating wet and dry phases with temperature cycling accelerate natural weathering processes that vehicle components experience in real-world service.

Have a question? Contact us!

Our most common corrosion tests

Talk to our corrosion test experts

Are you interested in conducting a test? Feel free to contact us – we’re here to assist you every step of the way.

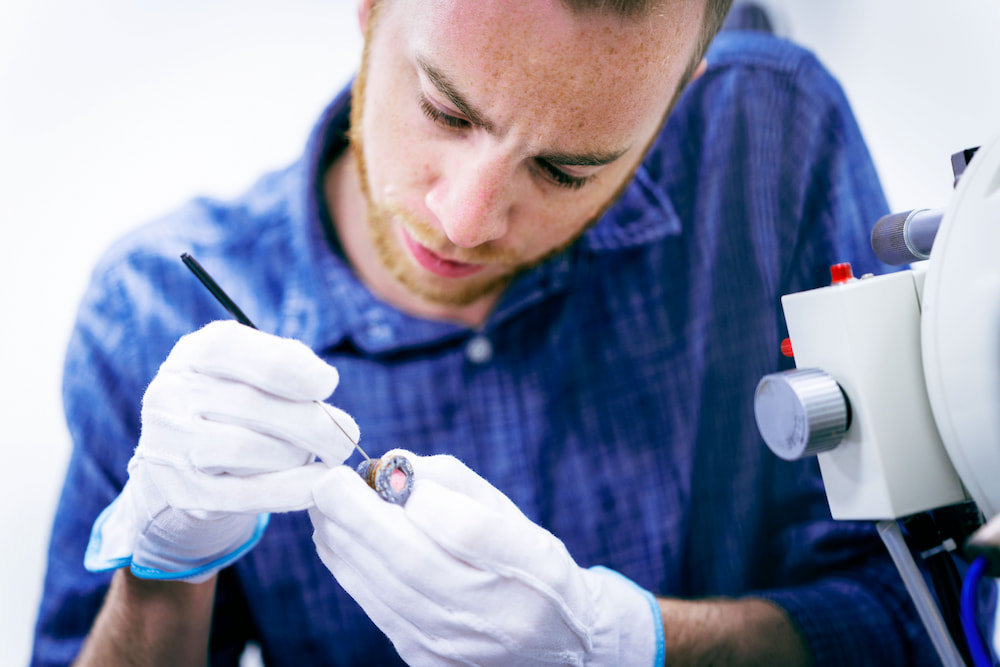

Joakim Ekström

Erik Waltersson

Accredited by SWEDAC

and part of the international accreditation network ILAC

Methods and requirements

We offer a comprehensive and continuously expanding lab-scope of over 300 available test methods and standards.

Laboratory and equipment

Cotec Labs provides a 1200 sqm laboratory facility. Take a closer look at our laboratory

and equipment.

Quality and certificates

We are accredited by Swedac and part of the international accreditation network ILAC.